3D Laser Scanning

I am creating and Adapting Reuse Efficiencies with 3D Laser Scanning.

As new building technologies create efficiencies in energy, water, and indoor air quality, there will be a regulated push to upgrade existing structures. Bringing on these technologies may require a remodel and a retrofit of MEP installations. Adaptive reuse projects, or modifying pre-existing structures for a new purpose, are on the rise and tend to be complex. This Building for Life post discusses 3D Laser Scanning, an efficient way to size up complex projects like adaptive reuse.

ADAPTIVE REUSE, A COMMUNITY BENEFIT

Adaptive reuse projects are great for the community. These projects result in building material cost savings. These structures are already set-up with water, wastewater, and utilities therefore installation of new infrastructure is not needed. Adversely, some of these sites may be contaminated and need remediation. Despite the upfront costs to adaptive reuse projects, there are tremendous benefits including a growth of a local tax base, more jobs, cleaner environment, and community revitalization.

WHAT IS 3D LASER SCANNING?

3D Laser Scanning (also known as lidar) is the controlled steering of millions laser beams with a laser rangefinder. The rangefinder’s high-speed scan emits laser light to accurately and precisely calculate the measurement of 3D dimensions and spatial relationships. The scan provides a full 3D model combining multiple surface models obtained from different viewing angles that are generated by millions of data points invisible to the human eye. The result is an accurate depiction of the site, also known as the point cloud.

In addition to the point cloud data, the scanner obtains 360 degree photos from each scan point. This deliverable provides the viewer with high resolution observation capability from any remote location using a cloud-based application.

Laser Scanning provides tremendous benefit to construction activities and can be applied to:

Building Information Modeling

Virtual Design and Construction

Quality Control during Construction

Comparing the Design with As-built Conditions

CREATING EFFICIENCIES WITH AN INTEGRATED APPROACH

An integrated approach is the key to success. This approach brings all project stakeholders together early on with the intent to address potential challenges in the areas of identifying structural and/infrastructure requirements for the new use, addressing environmental concerns like the presence of mold, asbestos, lead, and meeting regulatory requirements such as building codes and zoning ordinances. One of the best ways to commence an integrated approach is to generate 3D laser scans of the existing structure. This approach will enable the following benefits:

A fast and accurate means of collecting millions of measurable data points in seconds with pinpoint accuracy.

Datasets are dimensionally accurate, measurable, and shareable, which eliminates guesswork.

When your project is complex with detailed MEP, like an adaptive reuse retrofit, you can capture precise data over the full range of measurement.

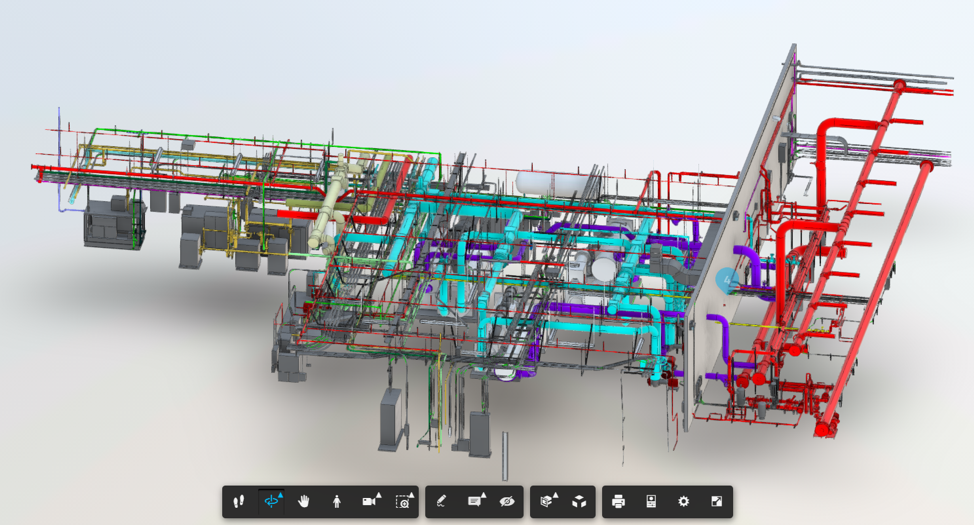

CASE STUDY: CENTRAL UTILITY PLANT

GMH Builders recently completed an As-Built BIM for one its confidential clients. The goal was to not only collect as-built conditions, but leverage it for new upgrades during design. We collected element spacial conditions, accurately surveyed and identified all MEP Systems, Material Types, and Equipment identification. This was truly a team effort between GMH Builders and the Facility Management staff using the latest in collaboration software for efficient means of communication both on site and remote.

Prior to performing this task, GMH studied the Return on Investment (ROI) with the Owner, Design Team, and Trade Partners in conducting this level of service. We assessed the quantity of related field verification that would be required without this tool, extended the labor hour savings if performed, and easily determined the ROI over a short time period. We further honed in on the scope of as-builting conditions, determining areas planned for complete demolition were not of value to model, however they were scanned for documentation purposes for little cost. Additional savings in cost and time during construction were known to have future additional benefit that made the case even more clear that this service provided the team had tremendous benefit.

As community builders, we believe adaptive reuse is a winning strategy. Existing structures have enormous intrinsic value. There a number of underused buildings that have the potential to create value and save on project costs. Taking a creative approach and utilizing the latest construction technologies, like 3D laser scanning, to create project efficiencies will encourage others to imagine how a building conversion can help them with their future growth.

What is your experience with laser scanning? Please share your experience with us in the comments section provided below.